How to use Epoxy resin glue ?

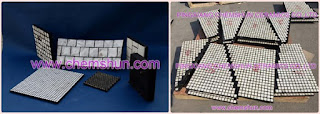

How to use Epoxy resin glue ? Pingxiang chemshun ceramics co.,ltd is a professional manufacturer of wear resistant ceramic & ceramic grinding media, afford the high quality epoxy resin glue (also called Epoxy structure adhesive) to paste our alumina ceramic linings on the applied equipment, and ceramic coatings apply directly to the surface of equipment. Choose high quality epoxy resin glueand the correct fixing method is the first prerequisite to prevent the shedding of ceramic linings and improve the durability of the equipment. Here is Chemshun recommend the Epoxy resin glue and the correct using method for your reference. Epoxy Glue is liquid of ingredient A and B, it has low shrinkage ratio, low exothermic temperature .after curing , its feature is anti-cracking and moisture protection as well as good insulation. According to the using temperature Chemshun ceramics have 3type of epoxy resin glue. Type 1: -60~150 ℃, Type 2:-60~200℃, Type 3:-60~320℃. How to use the ep