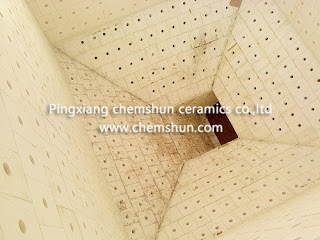

Chute ceramic liner supplied from China Factory

Chute ceramic liner supplied from China Factory Chute equipment is usually on the ground from the top to the bottom of the operation of the slot, materials can automatically slip off ,such as gold ores or sand,coal. Generally chute ceramic liner is necessarily considered when installing chute ,because is an integral part of chute conveyor system. Chemshun Ceramics help customer to design, produce,install chute liners with customized size. How to install alumina chute lining ? We would like to share with you the tips. Paste type include alumina ceramic plain tile and ceramic rubber sheet. This method is simple device, lower cost, especially suitable for large-scale construction site, saving time for maintenance. However, because the viscose is mainly organic components, not high temperature resistant (high temperature up to 150 ℃), and easy to aging Weldable chute ceramic liner include weldable tile liner, the installation way is combination of welding and adhesive. So it is fit