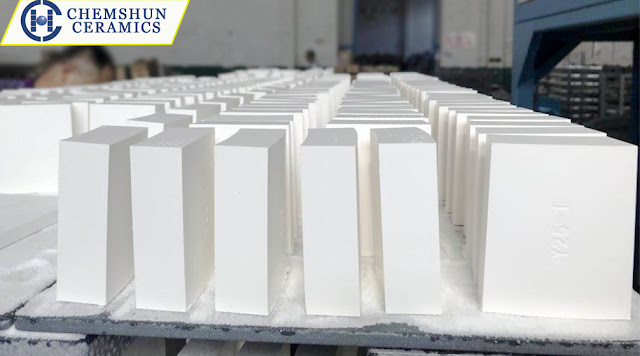

Factory Ceramic Saddles as Heat Transfer Media Manufacturers

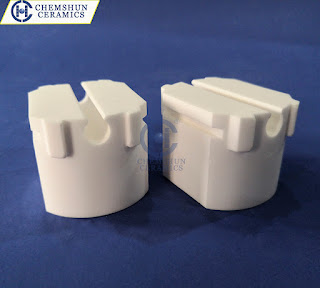

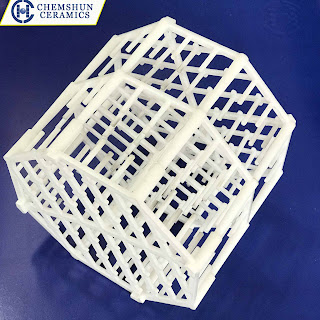

Ceramic intalox saddle has excellent acid resistance and heat resistance. It can resist corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions. Consequently the application range is very wide. It can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc. Application: Saddles are used in two main fields but have different properties depending on the application. One field is the chemical and petrochemical industries and another is in environmental areas such as RTO equipment. Here we introduce the ceramic saddles (Type B) are used as the RTO and heat transfer medium. These saddles are made from chemical porcelain and have excellent resistance to acids except in the case of hydrofluoric acid. Mostly used as heat transfer media and are of much highe