Six Features for wear resistant ceramics, abrasive metal materials can not match

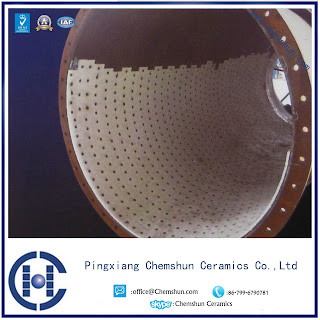

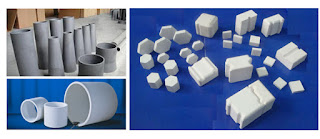

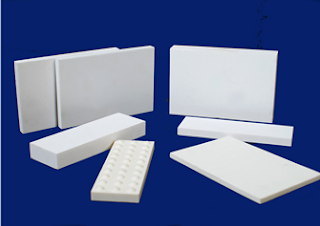

Chemshun Wear resistant ceramics in industrial production can solve difficult high wear damage, it has the following six performance characteristics, metal materials can not match. 1. hardness It was determined the CAS Shanghai Institute of Ceramics that, Rockwell hardness HRA80-90, hardness only to diamond, far more than the wear resistant steel and stainless steel. 2. Excellent wear resistance Determination from Powder Metallurgy Institute of Central South Great shows that the wear resistance is equivalent to 266 times the manganese steel, high chromium cast iron 171.5 times. Based on chemshun ceramics 13 years follow-up survey of customers, in the same condition, it can extend the life of the equipment at least ten times or more. 3. Light weight A density of 3.5g / cm3, only half steel, can greatly reduce the equipment load. 4. Firm adhesion, good heat resistance Chemshun wear resistant ceramics adopt strong heat-resistant glue pasted in the inner wall of the indust