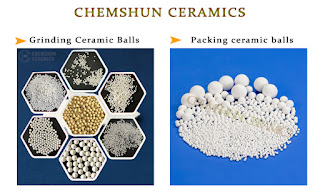

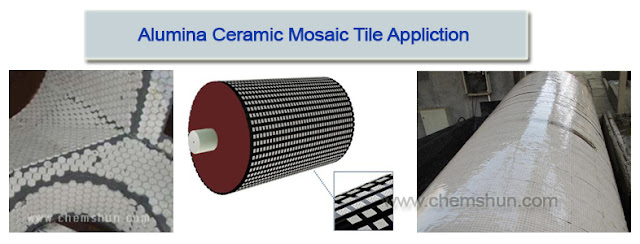

Classification of Wear Resistant Ceramics

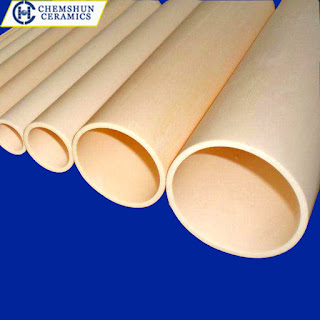

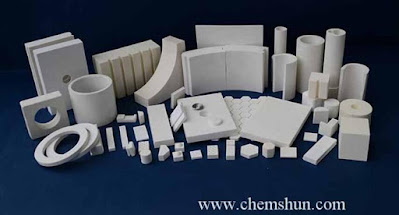

Wear resistant ceramics is wear protective liners for industry machines. Different material ceramics have various physical and chemical property ,popular materials includes alumina ceramics, silicon carbide, zircon toughened alumina ceramics etc. But In the actual construction and installation process, ceramic shape is much important to Suit for mechanical parts size and shape. Chemshun Ceramics manufacturer supply all the abrasive ceramics shapes with most common materials .Take ceramic plates as example. Chemshun abrasive alumina tile include plain tile, trapezoidal tile, curved tile,weldable tile with various sizes, most of them are installed by epoxy adhesive, but except for welding plate,which is supplied together with steel plug and alumina dot for special working environment of high impact and temperature. 150x100x13mm, 150x100x25mm, 150x100x50mm are popular tile sizes,surely customized engineered tiles can be offered by CAD design according to customer equipment drawing. Bes