How to repair the ceramic chute liner

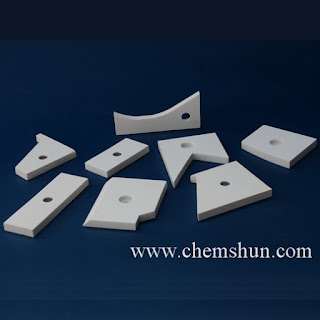

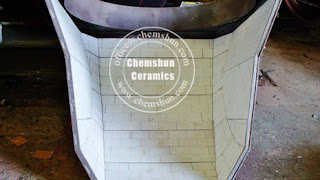

How to repair the ceramic chute liner manufacturer and exporter,typical ceramic plain tile,ceramic weldable sheet, rubber ceramic wear liner is popular ceramic chute liner ,but for a long time working,alumina ceramic tile liner may loose or fall off. which will affect chute working efficient .So Chemshun Ceramic factory tell you how to repair the ceramic chute liner First take down the loosing ceramic tile and check the sorrounding tile wether they are loosing by hammer. Second cleaning the chute surface where ceramic tile was taken down. Third applying the mixed epoxy resin adhesive on the chute surface ,than carefully put the new ceramic chute liner on the epoxy resin adhesive. At last beat the new ceramic tile in order to fix it. the surrounding loosing tile also need to be replaced like this . If the ceramic chute liner is rubber ceramic wear liner, the easy way is to loosen the screw of bolt and install a new ceramic wear plate. To a