Large-scale High-purity Alumina Ceramic Products Produced By Spontaneous Solidification

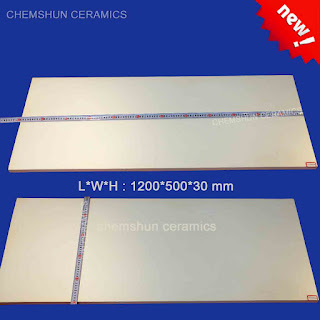

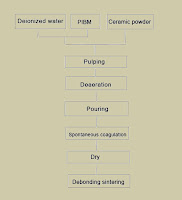

spontaneous gelation breaks through the key bottleneck problems such as deformation and cracking of large-size ceramic wet billets during drying, and produce large-size high-purity alumina ceramic grinding discs with diameters of 360mm to 600mm, 1400x900x30, 500x500x45, 1180x490x20mm etc . Large-scale structural ceramic parts have a wide range of applications in Semiconductors Manufactur, LCD Equipment, General industrial Machines and other fields, but the molding of large-scale ceramic parts is extremely challenging. Compared with classic cold isostatic pressing and injection molding, gelcasting (gelcasting, or gel injection molding) has outstanding advantages: the green microstructure is uniform, fundamentally ensuring the reliability of ceramic components; The billet has high strength and density, is convenient to handle, and can effectively reduce the risk of sintering shrinkage and cracking; near-net-shape molding can greatly reduce the machining cost. In addition, the inject