what material is used to make bulletproof vests

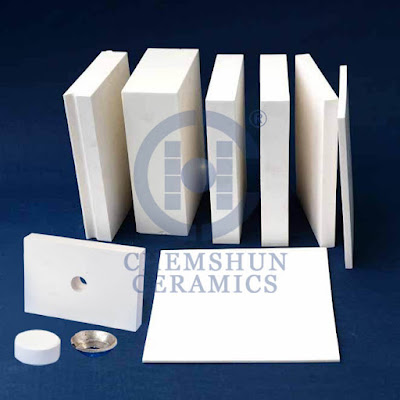

Steel plate is the earliest material used in hard body armor panel , which greatly improves the protection level of soft body armor, but the protection ability is limited, it can only defend against the attack of lead-core bullets and ordinary steel-core bullets, and it is too heavy and easy to attack. Disadvantages of ricochet. Compared with the steel plate, the performance of the ceramic material has been improved, the light weight and density are less than 1/2 of the steel plate, and there is no ricochet phenomenon. Among the commonly used bulletproof ceramics, B4C, Si3N4, SiC, have outstanding bulletproof performance, but the price is high, while Al2O3 military armor ceramics have the advantages of low price, mature technology, easy size control, low sintering temperature, and easy mass production. Universal material Pingxiang Chemshun Ceramics is a professional manufacturer of alumina bulletproof body vest ceramics . The company mass-produces protective ceramics to provide s...